I-90 Corridor Aerospace Expo Attracts Industry Leaders

June 26, 2017

The I-90 Aerospace Expo was held at the end of May in beautiful Coeur D’Alene, Idaho. Over 50 companies exhibited in the trade show portion of the event. Key speakers included executives from Boeing Aerospace and Crane Aerospace and Electronics. Panel presentations ranged from topics such as upcoming changes to AS9100, to a very interactive discussion of the challenges faced by small businesses in doing business with larger aerospace OEMs. The Inland Northwest Aerospace consortium sponsored the event in conjunction with it’s sister organization in Idaho, the Idaho Aerospace Alliance. Both groups believe that the inland Northwest will see accelerated growth of aerospace-related businesses in the in the inland Northwest, as the I-5 corridor starts to run out of available infrastructure for manufacturing..

Come See Us Next month at the AMCON Show in Bellevue

March 27, 2017

Come see us next month at the AMCON

show in Bellevue, booth #217. This is a great regional show for manufacturing companies on the I-5 corridor. We will have samples and staff there to discuss any projects that might be on your radar.Collaboration With Local Lenders

August 19, 2016

We recently had our banking partner, Numerica Credit Union, come to our facility to make a promotional video about us, focusing on their support for helping small businesses scale up. It features our owners and partners, Matt Sarner and Bruce Colwell.Water, Water Everywhere

May 16, 2016

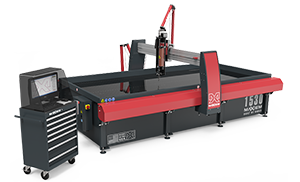

We are excited to announce that our

Omax Maxiem Waterjet is up and running. This new resource will allow us to fabricate custom gaskets from just about any kind of material, without any tooling costs. It’s a perfect solution for small volume or R&D projects. Please contact us if you have a project that you would like to discuss!AMCON 2016 in Bellevue Shows Strong Attendance

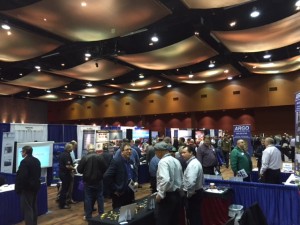

March 22, 2016

We recently exhibited at the AMCON show in Bellevue, WA. There was a lot of activity in the exhibit hall, particularly from the SMB segment of the market. From what we saw, the recent positive forecasts regarding the strength of the aerospace industry in the Northwest look to be correct.

(See EDC INSIGHTS article)There are also a growing group of creative start-ups, including companies like

Pure Watercraft who are working to develop a commercially viable all-electric outboard motor for the marine industry. Innovation is alive and well in the Northwest!Welcome To Our New and Improved Website

December 1, 2015

Our very own IT Manager Mark Tuttle has recently redesigned and coded our website.

After a few hiccups with our host, all systems are go.

In the next few weeks, we will be adding a section for design guidelines / artwork requirements, and will update the site to provide a better Mobile experience.

Westec Show Finished... Manufacturing is Alive and Well

September 21, 2015

Great show at WESTEC last week in Los Angeles. Lots of interesting technology on display, and good crowds all 3 days. We are seeing increasing demand for rapid prototyping and product development, and I think that bodes well for growth in the manufacturing sector in coming months.

Aerospace in particular seems to be strong, and that is a major focus for us in 2016. We are awaiting our ITAR certificate and looking at a push towards AS9100 compliance as well. Industry experts expect 200% growth in this market sector in the next 5 years.

Lightweighting

August 26, 2015

“Lightweighting” is becoming a buzz-word in industrial manufacturing and design. It refers to the process of designing or modifying a product to reduce weight. By reducing weight, you reduce transport costs as well as total consumption of resources, and lighter can also frequently translate into a lower profile design for consumer electronics, etc.

At Eclipse we can work with your team to suggest pressure sensitive diecut parts for mechanical assembly, or ultra-thin thermal and conductive adhesives for replacement of thicker/heavier alternatives.

Call us today to discuss how we can work with your team to find a better solution!

Breaking Ground

August 7, 2015

Eclipse will be exhibting at the WESTEC 2015 show next month in southern California. This is one of the largest manufacturing-oriented shows held annually in the USA, and there should be a lot of interesting technologies on display.

We will be in booth 450- we hope to see you at the show!

New Additions to Sales Team

July 23, 2015

We are excited to announce two new rep firms to help us in our sales efforts:

Clarknet (www.clarknetsolutions.com) will be covering Oregon, Southern Idaho and parts of the I-5 corridor for us in the Northwest.

RMB Consulting (Kevin@advpack.com) will be our representatives in California and the Southwest.

Please join us in welcoming these new members to our team, as we continually work to provide better service and response time to our customers!

Prototyping With Digital Technology

June 26, 2015

As anyone in the real world of manufacturing knows, a product design seldom makes it from the CAD station direct to the production floor without some iterative changes. The key to fine-tuning a product design often means very small production runs that allow the design team to see what changes need to be made.

At Eclipse, our laser and digital UV printing systems are a perfect fit for this process. We can move directly from a digital file to printed or cut part, without having to create expensive tooling in the process (plus the added time for that tooling to be fabricated). This gives our customers flexibility in playing around with design options with very little investment in set-up.

Contact us today to discuss your project.

Design 2 Part Show, Santa Clara

May 26, 2015

We just returned from the Design 2 Part Show in Santa Clara, California. Along with a few hundred other exhibitors, we spent 2 days talking with engineers and designers from OEMs all over the west coast. Although the manufacturing market remains challenged to achieve growth in 2015, we were impressed by how many start-up companies came by to talk with us. And that’s a good thing- we believe that innovation will continue to be America’s competitive edge in the global market.

Report - AMCON 2015 in Bellevue

April 23, 2015

Amcon 2015 in Bellevue, Washington was a great show for Eclipse. Attendance was strong and there was a lot of representation from the engineering and design disciplines at the show.

Aerospace continues to be a strong manufacturing sector in the Northwest, but we also saw good participation from the test and measurement market.

One of the primary needs across the different manufacturing sectors is for quick turnaround of R&D and product development efforts. This has always been one of our strengths, and we will continue to strengthen our toolkit for this in the future.

Eclipse at AMCON in Bellevue

March 10, 2015

Eclipse will be exhibiting at AMCON in Bellevue, March 24th and 25th of this month. AMCON is a major trade show and conference event for high-tech industries in the Northwest. Kelly Espe, our general manager, will be one of the presenters, giving a lecture on color science and management for the manufacturing sector. Please come visit us if you are in the Seattle area!

Aerospace Business Grows in Inland Northwest

February 16, 2015

Eclipse is a proud member of INWAC - the Inland Northwest Aerospace Consortium. INWAC is unique collaborative effort of various manufacturing companies in Eastern Washington that have banded together to market our area as a “one-stop shop” for the Aerospace industry. Whether a company is an aerospace OEM or tiered vendor, they can find just about any capability within the INWAC network- sheet metal, injection molding, part decoration, etc. In this age where competition becomes increasingly global, INWAC is a good example of how companies with different disciplines can work together to promote themselves to a common market.

New Cutting Capabilities Here at Eclipse

January 16, 2015

We are happy to announce a major equipment acquisition that will significantly expand our capabilities for gasket fabrication. We have purchased a waterjet cutting system from Omax Corporation that we plan to install in our new plant expansion later this spring.

This unit has a 5′x 10′ bed, so we will be able to fabricate parts in bulk, or manufacture parts with a very large footprint. The waterjet technology allows us to cut a huge array of materials, from very porous foam to hardened steel.

Stay posted as we will update you on the machine installation and the new additional space to our plant in the coming months.

Trade Show Schedule for 2015

January 9, 2015

We are looking forward to interacting with new prospective clients this year, as we begin to start our trade show marketing for the coming year. Currently, we are booked to exhibit at the AMCON show in Bellevue, Washington on March 24-25. We are also planning on exhibiting at the Design 2 Part Show in Santa Clara at the end of May.

For our existing customers who reside outside the Eastern Washington area, we look forward to catching up with you at one of these events.

If you are not a current customer, we hope that you will come by to say “hi” , so that we can learn a little more about you and your needs. We look forward to meeting you!

-Mark Norton, Manager of Sales & Marketing

Using Overlays For Nimble Manufacturing

December 1, 2014

We will occasionally have conversations with new customers about the pros and cons of using overlays versus printing directly onto the sheet metal or plastic housing.

If you make a number of similar models of products, with slightly different configurations- different knockouts, languages, etc- it is much more efficient to carry an inventory of generic boxes and customize/configure those with overlays, than to stock separate printed units of each model. This fits a nimble fulfillment model for quick turnaround, as well as reducing inventory investment.

Other benefits include the ability to incorporate features such as light pipes/indicators into the overlay, reducing part count and overall cost. And because the overlays are reverse-printed (i.e., the graphics are behind the front surface of the film), they are much more durable than graphics which are printed onto the surface of the part.

UV ink technology and it’s benefits for OEM decoration

November 14, 2014

At Eclipse, the vast majority of our work is done using UV ink technology. This is a paradigm shift from the old days of screen printing, where solvent-based inks dominated, with all the resultant aroma and recovery/disposal procedures that came along with them.

UV inks are cured with an short burst of intensive UV energy. It is much more akin to a polymerization process than printing, causing a cross-linking of ink molecules into an almost plastic-like coating. Cure time is almost instantaneous, and the inks are much more durable. Additionally, we can use “texturing inks” to selectively apply textures on a surface, resulting in scratch-resistant zones in high-wear areas, and leaving crystal clear zones for LEC/LCD displays, etc.

Call us today to discuss which printing process is the right fit for your project.

About Our News Page...

October 1, 2014

The news area of our site features tips and articles about designs and processes for our industry, trends and new technologies for the markets that our customers serve, and any other fun and informative topics that we feel might be of interest to our customers. We will have regular posts here to share new capabilities with you, as well as to update you on new trends on product decoration and membrane switch technology. We welcome your input about concerns, areas of interest, new technologies and whatever tickles your fancy.

Membrane Switches for Test & Measurement Devices

September 26, 2014

Test and Measurement Devices are often used in shop and field environments that require a rugged user interface. Moisture and other ambient factors can be present on the shop floor or out in the field, and if they find their way into the interior of a test device, they can cause poor performance or total system failure.

Membrane switches can provide a sealed input system that helps to insulate internal electronics and other sensitive components from hostile environmental agents. Light channels, scratch-resistant or textured materials, and scratch-resistant coatings are technologies that can all be employed to provide you with a durable, flexible switch with high actuation life.

Feel free to contact us about collaborating with your team on your next test and measurement system.

Digital Printing Services – Fast & Flexible

September 26, 2014

Our digital printing services can offer some significant advantages over traditional screen printing in specific applications.

Photographic, 4-color images can be rendered in very high detail. And because images are printed individually, text information can be customized for each impression with a unique title, barcode, QR code, etc.

Digital printing cannot typically compete on a cost basis if you are looking for a higher volume of parts, because the printing process is significantly slower. But there is no tooling or screen-creation involved- the preparation is just a fairly simple formatting of the art file. This means no tooling cost and lead time on smaller volume runs.

When combined with laser cutting, digital printing can be the perfect solution for iterative product development and prototyping, as well as short-run production. Call us today to discuss your product, and whether this technology is the right fit for you.

Fusing Art and Technology

September 12, 2014

Technical screen printing is a manufacturing segment that is part art and part science. On one hand, we work with aesthetic parameters like color, fonts, and graphics. On the other hand, we also construct flexible circuits and membrane switches where we need to assess functional parameters like circuit resistivity and actuation force.

Aesthetic and functional considerations can often impact each other, and what seems initially good at the design phase may not be practical for manufacturing at scale. A good example is line weight (width) in artwork. Most people work from CAD or design software these days- and a thin/elegant line (or graceful font) that looks good on your computer screen at 3X scale may be hard to see/read when it comes off our printing line.

We will work with your team to make sure the need for innovative and distinctive design is balanced with your functional requirements, and that DFM (design for manufacturing) is also part of the mix. At Eclipse, we believe that is the difference between a vendor and a business partner.

Aesthetics and Color

September 12, 2014

One of the critical components of nameplates, overlays and labels is color. Consistency of hue and tint from one production lot to the other is essential for most of our customers.

Visual inspection is one component of assuring color consistency, but it is also a somewhat subjective assessment that can vary from one viewer to the next (did you know that women see color more accurately than men?). Light source, viewing angle, etc can all affect how we perceive color.

At Eclipse, we use a spectrophotometer to quantify colors via the LAB colorspace model. The numerical data that we collect is something that we check on every lot of product that we run, to make sure each lot of product falls within a specific tolerance range of the desired color. And that is one of the ways that we blend art and science at Eclipse to make quality product for our customers.